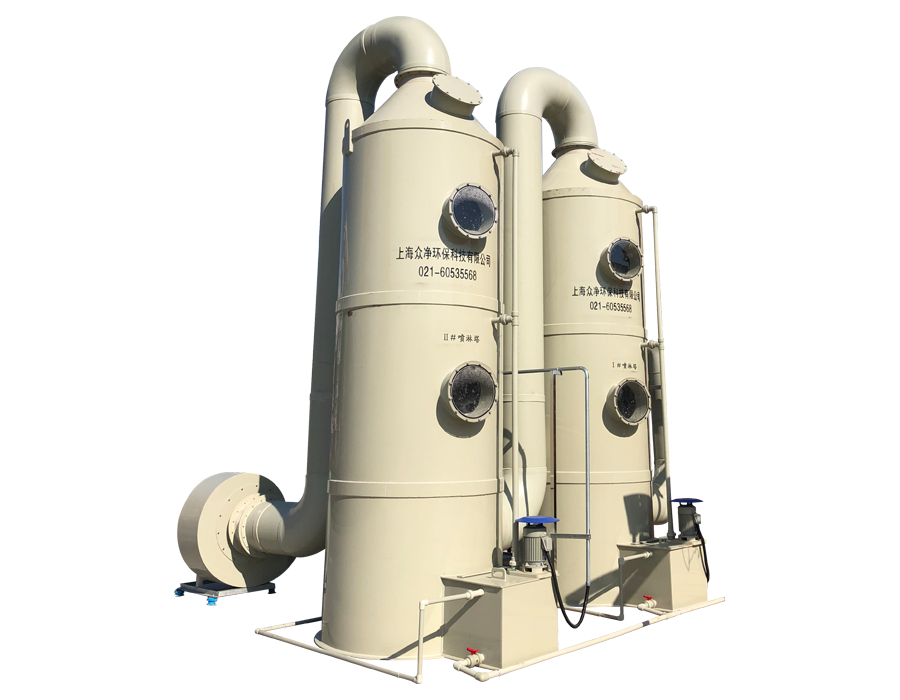

Spray tower

Click:4022Date:2021-05-09 07:33:23

Spray tower for waste gas treatment

Waste gas purification tower, also known as acid gas purification tower, acid mist purification tower, acid mist absorption tower, waste gas purification tower and glass fiber reinforced plastic acid mist purification tower, plays the role of removing harmful gases in waste gas, with a wide range of applications, high purification efficiency, low equipment resistance, small floor area and other characteristics.

For the treatment of corrosive gases (such as acid and alkaline waste gas), the most commonly used method is liquid absorption. The key to control the waste gas by liquid absorption method is the selection of acid mist purification tower. Acid mist purification tower has the characteristics of high purification efficiency, simple operation and management, long service life, etc. it is the most commonly used acid and alkaline waste gas purification process and equipment. It has the characteristics of simple structure, low energy consumption, high purification efficiency and wide range of application, and can effectively remove water-soluble gases such as hydrogen chloride (HCl), hydrogen fluoride (HF), ammonia (NH3), sulfuric acid mist (H2SO4), chromic acid (CrO3), hydrogen cyanide (HCN), alkali vapor (NaOH), hydrogen sulfide (H2S), formalin (HCHO).

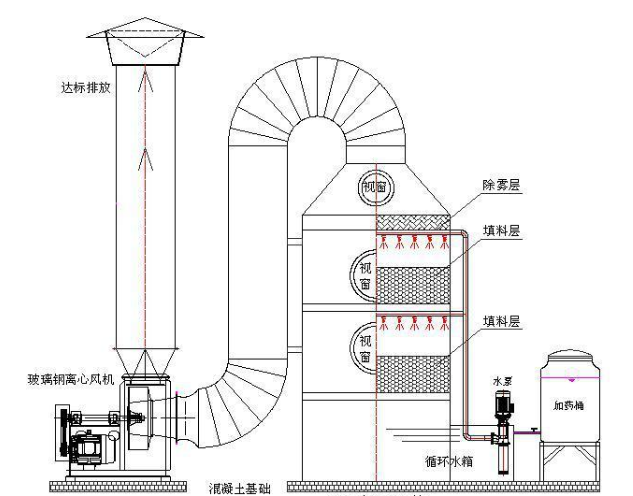

The waste gas is introduced into the purification tower through the air duct and passes through the packing layer. The gas-liquid two-phase full contact absorption and neutralization reaction is carried out between the waste gas and the absorption liquid. After purification by the purification tower, the waste gas is dewatered by the demisting plate and then discharged into the atmosphere by the fan. The absorption liquid at the bottom of the tower is sprayed at the top of the tower after being pressurized by the water pump, and finally returns to the bottom of the tower for recycling. The purified waste gas reaches the local emission standards.

Home

Home 139 5112 7702

139 5112 7702 To Consult

To Consult