-

Principle and application of injection plasma technology

In the process of modern agricultural production, industrial manufacturing, electronic coating, sewage treatment, garbage treatment and composting, a large amount of odor and organic waste gas with peculiar smell will be produced.

-

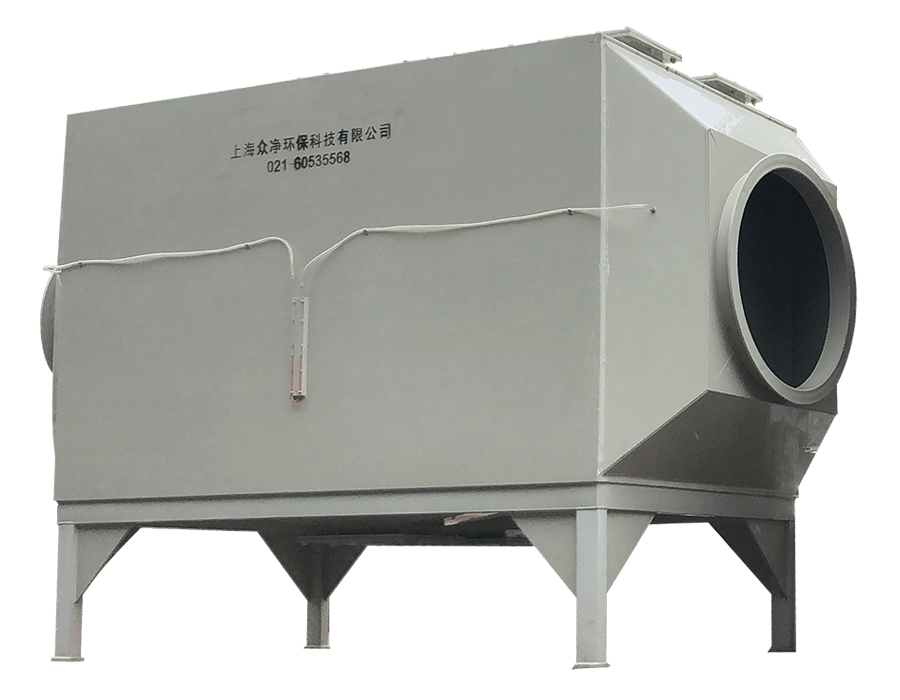

Injection plasma

Zj-dl-k plasma injection system of Zhongjing is composed of filter unit, current sharing hood, dehumidification and drying device, buffer bin, ion generation module, air conditioning unit, air conditioning unit and so on The number of modules is selected according to the need of waste gas treatment.

-

Waste gas treatment of sewage station

Odor control is a difficult problem for people. Working and living in this stimulating and suffocating odor environment for a long time will make people feel unhappy, nauseous, heartache and depressed, and bring serious harm to human body.

-

Sludge waste gas treatment

Sludge odor is mainly composed of organic waste gas and inorganic waste gas (hydrogen sulfide, ammonia, methane, mercaptan and hydrocarbon) produced by natural volatilization. Sludge odor is characterized by complex composition, strong irritation and great harm to human body.

-

Application of ultra micro nano bubble technology in waste gas treatment

Superoxide ion nanobubble catalytic oxidation technology is to use the free radicals and active free oxygen in the nanobubbles to promote the reaction with the pollution source molecules and produce the mixture including negative ions, hydroxyl, atoms and free radicals. Although the electron temperature is very high, the temperature of heavy particles is very low, and the whole system is at room temperature.

-

Micro nano bubble high gravity waste gas treatment equipment

Micro nano bubble high gravity dynamic oxidation technology is an advanced oxidation technology applied in waste gas treatment. It is an integrated design of water collection, electricity and gas (micro nano bubble device, oxidation medium, high gravity dynamic bed), automatic control system, fan, etc. The whole system is compact in structure, beautiful in appearance and less in land occupation. It is suitable for new construction or upgrading of various waste gas treatment.

-

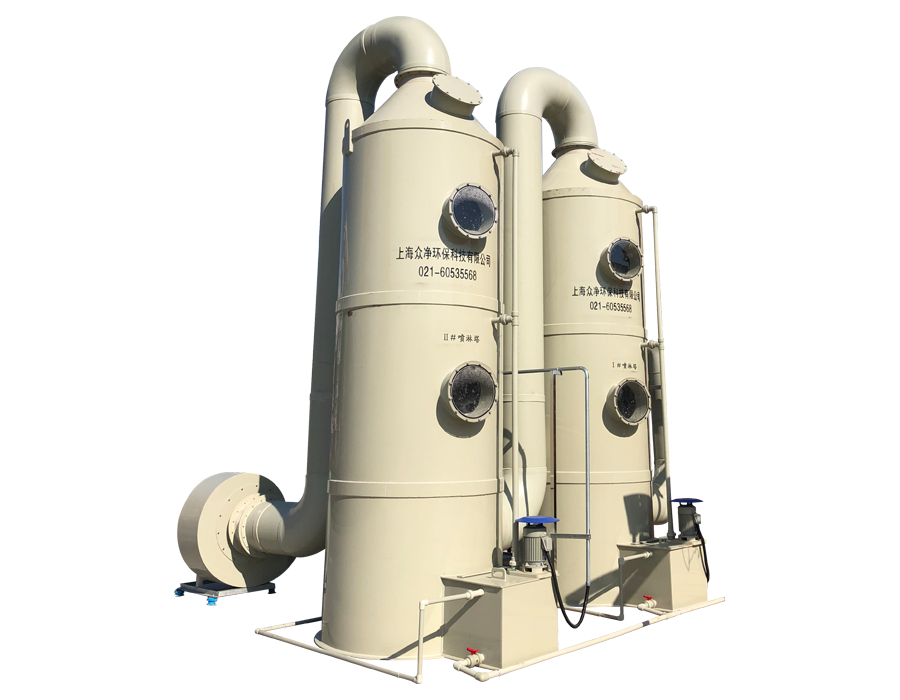

Spray tower

Waste gas purification tower, also known as acid gas purification tower, acid mist purification tower, acid mist absorption tower, waste gas purification tower and glass fiber reinforced plastic acid mist purification tower

-

Treatment of malodorous waste gas

Odor control is a difficult problem for people. Working and living in this stimulating and suffocating odor environment for a long time will make people feel unhappy, nauseous, heartache and depressed, and bring serious harm to human body. Shanghai Zhongjing adopts the latest zj-nm-c superoxide ion nano bubble deodorization purification technology, which can completely decompose the toxic and harmful substances in the odor gas, and can completely remove the main pollutants such as hydrogen sulfide

-

Waste gas treatment of pumping station

The waste gas and odor from sewage pumping station, anaerobic regulating tank, aeration tank and regulating tank mainly come from the waste gas pollutants contained in the wastewater itself, such as benzene series, lipids, ketones and alcohols, as well as the waste gas and odor from sewage and wastewater treatment process, such as nitrogen oxides, hydrogen sulfide, H2S, ammonia, sulfur dioxide, SO2, methane, CH4, mercaptan, etc.

Home

Home