Compressed air cold dryer

Click:3504Date:2021-06-08 10:32:53

Compressed air dryer is the use of refrigerant and compressed air for heat exchange, the compressed air temperature down to 2 ~ 10 ℃ range of dew point temperature, so that the moisture content of compressed air tends to supersaturated state, so as to remove the moisture (water vapor composition) in compressed air.

Product features:

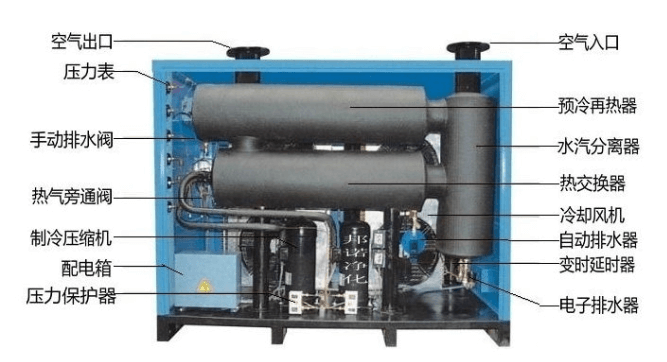

● High efficiency heat exchanger: use high efficiency large area heat exchanger. The pressure loss inside the dryer is reduced and the refrigeration effect is improved.

● No consumption of compressed air source;

● Built in automatic drain valve: it can ensure the water is separated from the system after the evaporator;

● No valve wear: no need to add or replace adsorbent regularly;

● Hot gas bypass valve: it is the key component to keep the dew point of compressed air stable;

● The operation noise of the equipment is low, and the daily maintenance is relatively simple. It is enough to clean the filter screen of the automatic drainer on time;

● Filtering device: the freezing dryer is equipped with high efficiency filter to keep the freezing system clean and durable;

● Refrigerant high / low pressure protection switch: the cold dryer has a perfect self-protection device to avoid damage to the refrigeration compressor;

● It has a "self-cleaning" effect on the exhaust gas, that is, the content of solid impurities in the exhaust gas is less;

● When the condensate is discharged, part of the oil vapor can also condense into liquid oil mist, which is discharged with the condensate;

● Reasonable design, compact structure, safe and stable, low energy consumption;

● The performance of the equipment is stable, the CPU integrated control is adopted, and the full-automatic operation can be realized.

Home

Home 139 5112 7702

139 5112 7702 To Consult

To Consult