What are micro nano bubbles? How are micro nano bubbles formed

Click:1653Date:2025-09-13 11:54:13

What are micro nano bubbles? How are micro nano bubbles formed

Micro Nano Bubbles (MNBs) are a type of tiny bubbles with diameters ranging from micrometers (1-100 μ m) to nanometers (1-1000nm), much smaller than traditional bubbles (typically>1mm in diameter). Due to their unique physical and chemical properties, MNBs are widely used in fields such as water treatment, agriculture, healthcare, and food processing. To understand micro nano bubbles, it is necessary to first clarify their core definition and formation mechanism. The following will be divided into two parts for detailed analysis.

1、 What are micro nano bubbles? ——Definition, classification, and core characteristics

Micro nano bubbles are not bubbles of a single specification, but are divided into two categories based on their diameter range: "micro bubbles" and "nano bubbles". The two have significant differences in size, stability, and function, and together form a system of micro nano bubbles.

1. Core Definition and Classification

According to international standards and industry practices, the classification of micro nano bubbles is mainly based on diameter:

Microbubbles: with a diameter range of 1-100 μ m, they can be observed with the naked eye under a microscope. Some larger microbubbles (>50 μ m) may appear weakly milky white in water.

Nanobubbles: with a diameter range of 1-1000nm (1 μ m), they need to be detected by precision equipment such as atomic force microscopy (AFM) or dynamic light scattering (DLS). They are completely invisible to the naked eye and can be stably dispersed in water to form a "transparent solution".

2. Core characteristics of micro nano bubbles (why have application value?)

The value of micro nano bubbles lies in the unique physical and chemical properties brought about by their size, which cannot be compared to traditional bubbles

Extremely low rising speed: According to Stokes' law, the rising speed of a bubble is proportional to the square of its diameter. The rising speed of nano bubbles is extremely slow, almost able to "suspend" in water, and can fully contact with water (contact time is more than 100 times that of traditional bubbles), greatly improving mass transfer efficiency (such as dissolved oxygen, decolorization, and pollutant degradation).

Huge specific surface area: The specific surface area (surface area per unit volume) is inversely proportional to the diameter. In 1L of water, if the bubble diameter decreases from 1mm to 100nm, the specific surface area will increase from 3m ² to 30000m ², which is equivalent to "opening up" a huge reaction interface and efficiently adsorbing pollutants (such as heavy metal ions and organic matter) in the water.

High stability and zeta potential: The surface of nano bubbles carries a large amount of negative charges (zeta potential is usually -30~-60mV), and the same charges repel each other to avoid bubble aggregation; At the same time, a stable "hydration film" will form on the surface of the bubbles, preventing them from bursting or merging, allowing them to survive in water for several days or even dozens of days.

Spontaneous generation of free radicals: Microbubbles gradually contract during their ascent (due to surface tension), and when they eventually burst, extremely high pressure (up to 100atm) and temperature (up to 5000K) are generated locally, triggering the cracking of water molecules to generate OH (hydroxyl radicals) - a strong oxidant that can efficiently degrade difficult to decompose organic compounds in water (such as pesticide residues and industrial wastewater).

The generation mechanism of micro nano bubbles

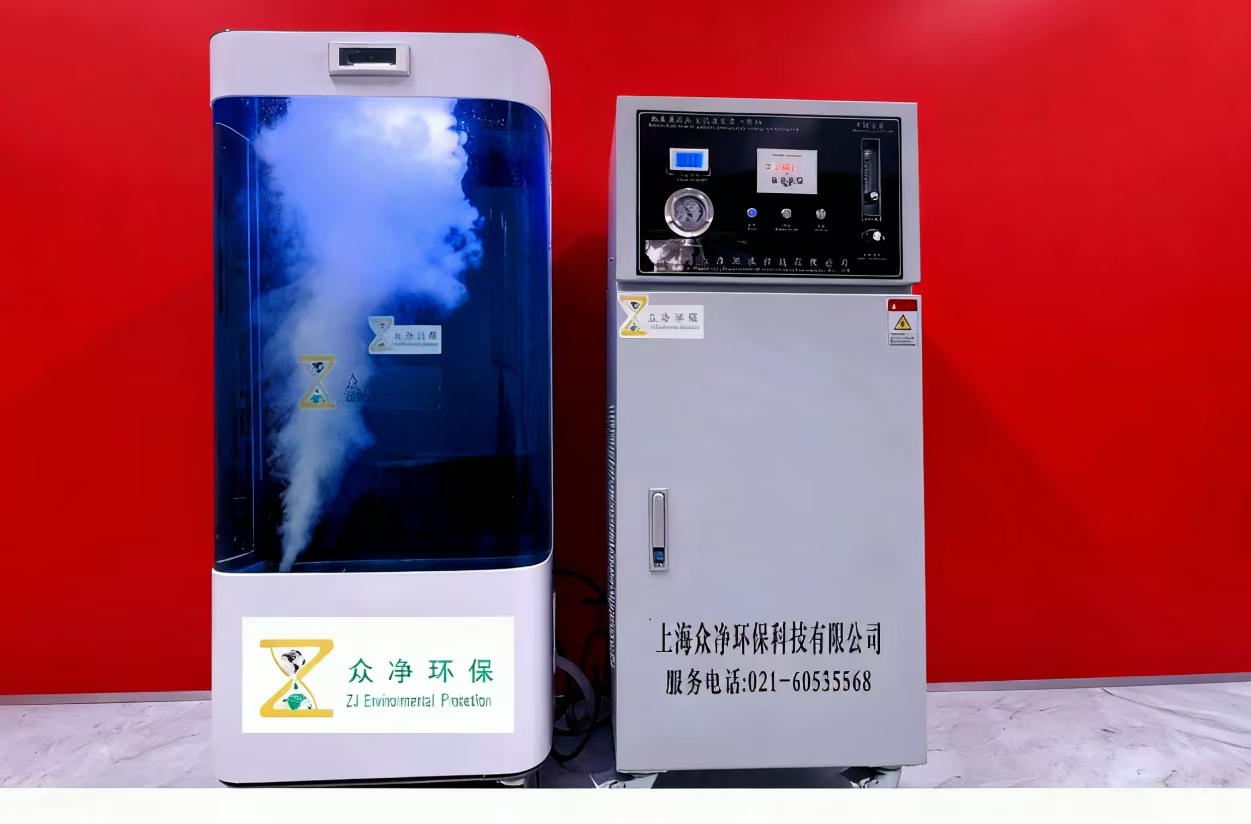

Shanghai Zhongjing Environmental Protection Technology Co., Ltd. specializes in the research and application design of micro nano bubbles. The generation principle of Zhongjing micro nano bubbles is mainly based on multiphase fluid vortex cutting technology, using a combination of hydraulic cavitation and vortex cutting technology to generate micro nano bubbles. The specific process is as follows:

Gas dissolution: A special device is used to dissolve gases such as air, oxygen, nitrogen, ozone, etc. into liquids, forming a liquid mixture rich in gases.

High speed rotary cutting: allowing gas-liquid mixtures to pass through a specially designed structure, utilizing the swirling field generated by high-speed rotation to fully mix gas and liquid. Under the strong shear force, the bubbles in the mixture are crushed. For example, by using high-speed rotary cutting method, the bubbles are chopped into several tens of nanometers to several micrometers, forming micro nano bubbles with particle sizes between 100 nanometers (nm) and 10 micrometers (μ m).

Bubble formation: After vortex cutting, the gas is uniformly dispersed in the liquid in the form of micro nano bubbles, forming a micro nano bubble system.

This generation principle makes the Shanghai Zhongjing micro nano bubble generator have the characteristics of small particle size, uniform distribution, large specific surface area, negative surface charge, long-term stability, self pressurization and rupture effect, and thus have wide application value in water treatment, exhaust gas treatment, industrial cleaning and other fields.

Home

Home