Rapid Odor Removal and Sludge Drying Exhaust Gas Treatment: Integrated Active Oxygen Micro-Nano Bubble System - Shanghai Zhongjing

Click:1412Date:2025-10-18 04:46:55

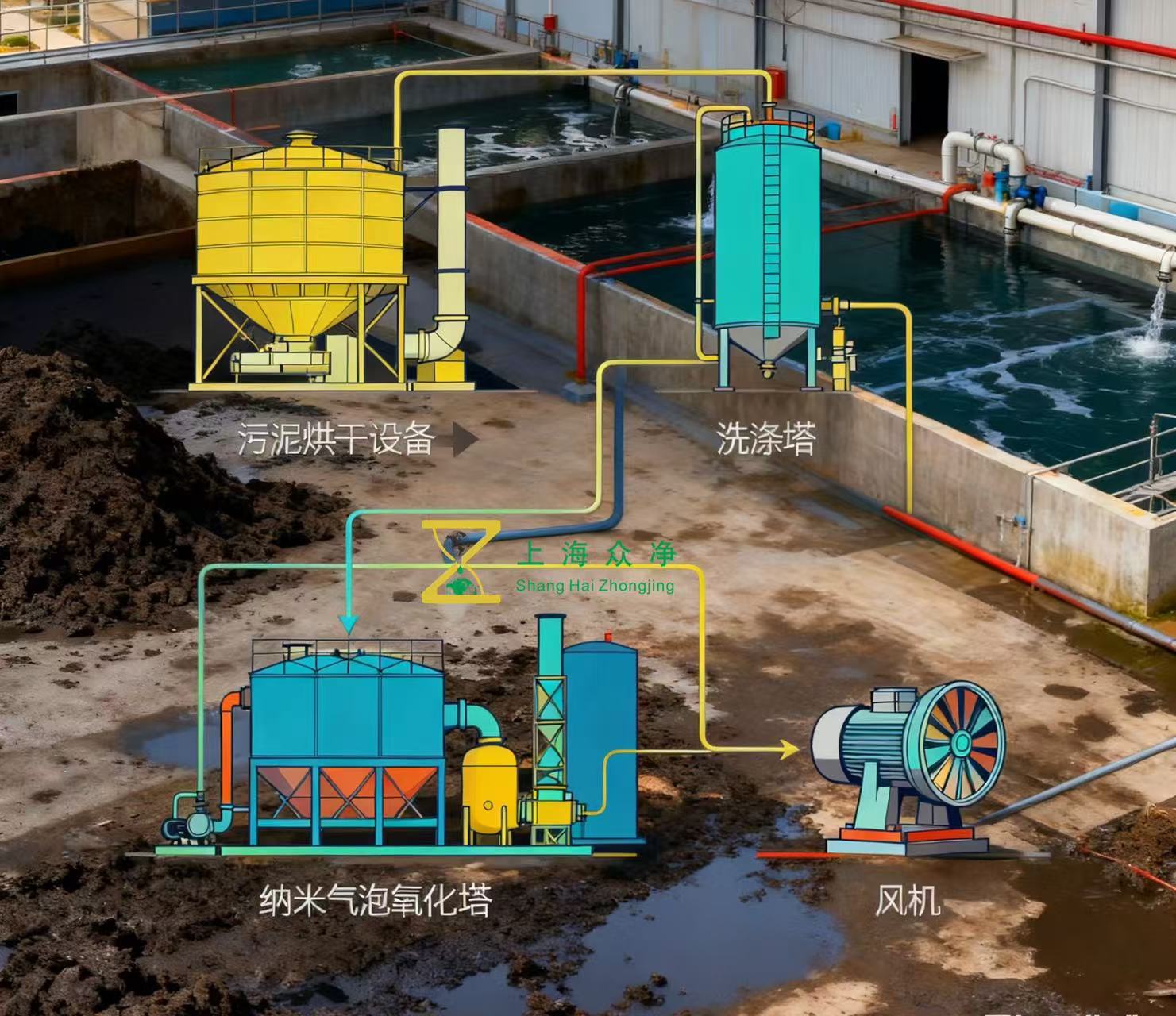

The active oxygen micro-nano bubble integrated device from Shanghai Zhongjing is a high-efficiency equipment for treating sludge drying exhaust gas, with the following relevant information:

Company Profile

Shanghai Zhongjing Environmental Protection Technology Co., Ltd. is a modern enterprise integrating R&D, manufacturing, sales, and services. It specializes in the research and application of ozone generators, micro-nano bubble generators, and injection-type plasma waste gas treatment equipment. The company possesses qualifications such as pollution control facility operation, environmental engineering general contracting, and environmental engineering design.

Technical Principle: The device utilizes mixed swirling to drive gases and liquids through microfluidic channel structures under pressure, achieving thorough mixing. It precisely cuts the gas into micro-nano bubbles with diameters ranging from 10 to 100 nanometers using specific shear forces. The high-concentration oxygen generation system inside the machine directly produces high-concentration nano-bubble water. The reactive oxygen components in the superoxygen micro-nano bubbles are chemically active, instantly releasing energy and a large number of oxygen ions upon rupture, forming highly oxidative hydroxyl radicals. These radicals rapidly react with harmful substances in exhaust gases, such as ammonia, hydrogen sulfide, thiols, and volatile organic compounds, converting them into harmless substances. Additionally, the micro-nano bubbles, with their extremely small diameters and large specific surface area, rise slowly and remain in water for extended periods. This significantly increases the contact area between gas and liquid, enhancing mass transfer efficiency and ensuring more thorough interaction and reaction between reactive oxygen and pollutants in the exhaust gases.

Equipment Advantages:

Rapid Deodorization: It can fully contact and react with malodorous substances, achieving a deodorization efficiency of over 90%.

Strong adaptability: Capable of handling various types of malodorous exhaust gases, it can effectively address complex working conditions such as high concentration, large volume, high humidity, high dust levels, and high temperatures.

Low energy consumption: Compared to some traditional exhaust gas treatment technologies, this device has lower energy consumption, which can reduce the cost of exhaust gas treatment.

No secondary pollution: The entire treatment process relies on the physical and chemical reactions of superoxygen micro-nano bubbles, with the final product being harmless substances. After the superoxygen reaction, it decomposes into oxygen, causing no secondary pollution to the environment.

Easy operation: The equipment features high automation, making it simple to operate and maintain. The intelligent control system can monitor and regulate the treatment process in real time, reducing labor costs and operational difficulty.

Application Fields: This device can be applied in the chemical industry, sewage treatment plants, livestock and poultry breeding, food processing, and other sectors. For instance, in sewage treatment plants, it can directly act on areas such as exhaust gas collection systems or aeration tanks to efficiently remove malodorous gases like hydrogen sulfide and ammonia. In the livestock and poultry breeding industry, pre-treated exhaust gases can be introduced into a superoxygen micro-nano bubble generation device, ensuring that the treated gases meet emission standards before discharge.

Home

Home