-

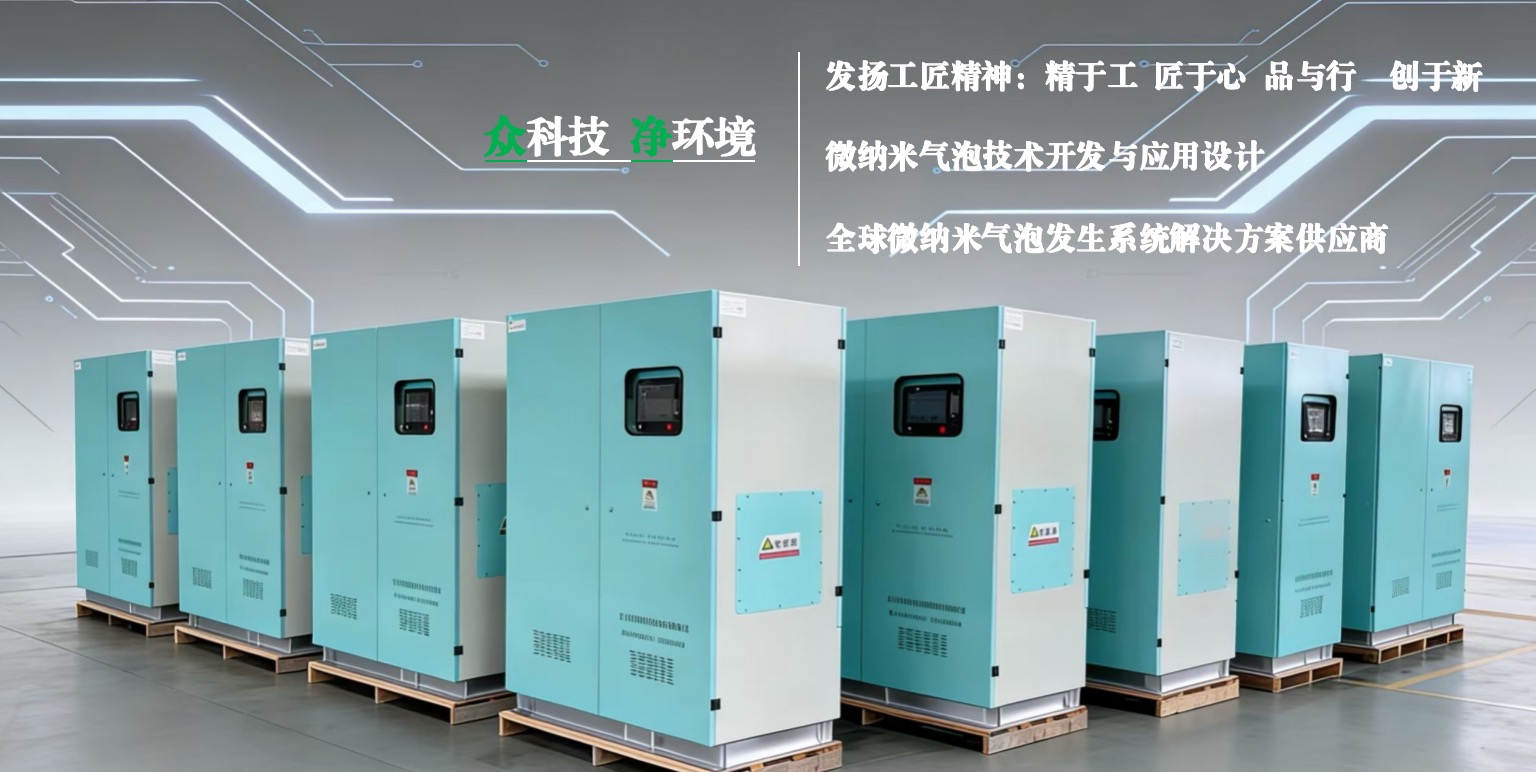

Happy New Year in the Year of the Horse 2026|Zhongjing Environmental Protection Embarks on a Green Journey with Micro-Nano Bubble Technology

2026-02-28 03:06:45

In 2026, Shanghai Zhongjing will continue to deepen its innovation in micro nano bubble technology, optimize product performance through technological iteration, enhance customer experience through professional services, help partners reduce costs and increase efficiency with more efficient, energy-saving, and reliable environmental protection solutions, and safeguard green mountains and waters with hard core strength.

-

Introduction to the Advantages of Micro and Nano Bubble Technology in Cleaning

2026-01-30 04:38:32

-

Introduction to the Principles and Application Fields of Ultramicro Nano Bubble Technology - Shanghai Zhongjing

2026-01-22 12:03:19

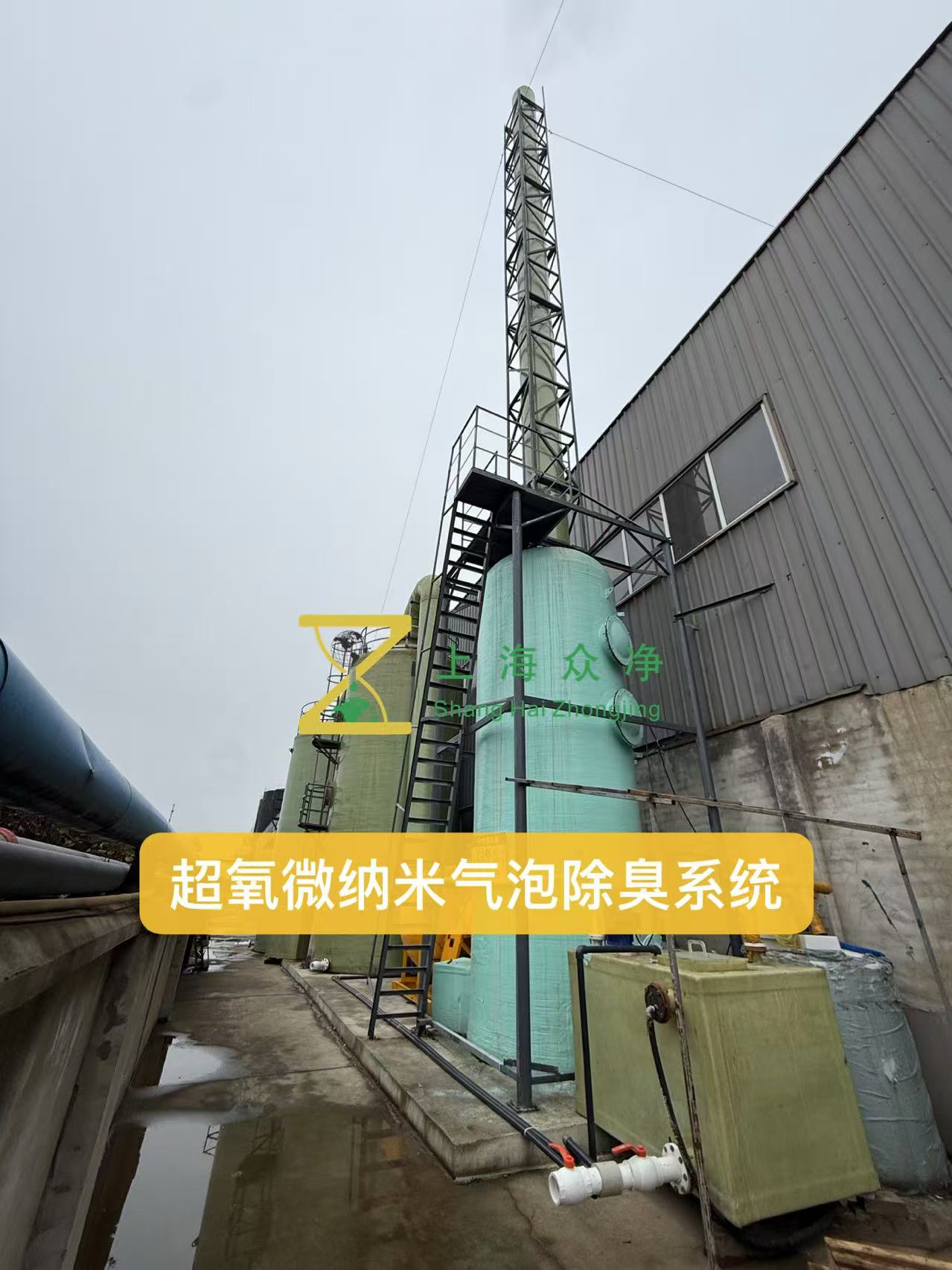

Ultra fine nano bubbles generally refer to bubbles with a diameter of 10-100nm. Shanghai Zhongjing uses multiphase fluid vortex cutting technology as its core, which combines the characteristics of ultra long residence, ultra high dissolved oxygen, and strong oxidation of bubbles. It achieves efficient applications in water treatment, waste gas/odor control, food processing, agriculture, and other fields, and the equipment is adaptable to extreme working conditions and can be intelligently controlled.

-

Advantages of Coupling Ozone with Micro/Nano Bubble Generators in Advanced Oxidation Technology

2025-12-23 11:56:07

The advanced oxidation technology coupled with ozone (O₃) and micro-nano bubble generators is a synergistic process that leverages the unique physicochemical properties of micro-nano bubbles to enhance ozone mass transfer efficiency and oxidation capacity, thereby achieving efficient degradation of pollutants in water or exhaust gases.

-

Application of Micro/Nano Bubble Cleaning Technology in the Ultra-Clean Semiconductor Cleaning Field - Shanghai Zhongjing

2025-12-13 04:28:31

Micro/nano bubbles, with their small volume and large specific surface area, can easily penetrate the fine gaps and pores of semiconductor chips. By leveraging the high-frequency vibrations induced by bubble movement and bursting, combined with the free radical reactions generated during bubble implosion, they can efficiently remove surface contaminants such as dust, oil, photoresist, and metal pollutants. Compared to traditional methods, the cleaning time is reduced from 5 minutes per cycle to 2 minutes per cycle, shortening the process time by more than 1/4. For instance, in post-IC manufacturing processes, this technology can significantly enhance cleaning effectiveness when applied in photoresist solvent solutions.

-

Application of Ozone Micro Nano Bubble Technology in Meat Processing Cleaning, Deodorization, Sterilization, and Preservation - Shanghai Zhongjing

2025-11-25 06:37:47

Clean the micro nano bubble generator, remove fishy odor, use the superoxide micro nano bubble device, sterilize the micro nano bubble generator, and use micro nano bubble technology for preservation

-

Micro-nano bubble irrigation technology for strawberry cultivation and its advantages

2025-11-25 04:33:04

Nano bubble technology adopts core technologies such as multiphase fluid vortex cutting. Firstly, gases such as air, oxygen, or ozone are introduced into the irrigation water, and then the bubbles in the gas-liquid mixture are finely chopped through high-speed vortex cutting, ultimately forming micro nano bubbles with a particle size of 10-100nm. These bubbles have the characteristics of long residence time and a dissolution rate of over 95%. They can be evenly dispersed in irrigation water and can accurately act on the soil environment of strawberry roots. At the same time, the equipment supports stepless adjustment of parameters such as gas flow rate and bubble particle size, adapting to the needs of different growth stages of strawberries

-

Application of Superoxide Nanobubble Hydroxyl Radical Oxidation Technology for Treating Drying Exhaust Gases from Pulp and Paper Mills

2025-11-15 04:48:29

-

ZJC-NM Series Micro-Nano Bubble Generator

2025-11-06 11:06:39

Shanghai Zhongjing holds multiple patented technologies in the field of micro-nano bubble technology, and its products have obtained certifications such as CMA, CE, ISO, and disinfection certifications. The company's products have received numerous national patents, and its brand clients include renowned enterprises and university research institutions such as CNOOC, Peking University, Tsinghua University, Fudan University, and Shanghai Jiao Tong University.

-

The Advantages of "Water Nourishes All Things" Micro-Nano Bubble Technology in the Agricultural Sector

2025-10-23 03:03:33

When micro nano bubbles rupture, a small amount of hydroxyl radicals (· OH) are generated, which can oxidize and decompose some pathogens and harmful organic matter. This can reduce the incidence of crop diseases, decrease the use of chemical pesticides, and promote the development of green agriculture

Home

Home